One of my “am I really the only one who sees this problem?” complaints is about the lack of cream at coffee houses. You can find various kinds of flavorings, ‘creamers’ and ‘whiteners’ but the state of the art at most places seems to be milk or, at best, half-and-half. I’m actually more upset about vendors considering any white substance cream and customers accepting it. (I recently had a 10 minute discussion with a barista about their lack of cream while she stared at me quizzically with a carton of half-and-half in her hand saying “But I just refilled the creamer!?!?”). We both walked away scratching our heads.

In the HR/PR/Kronos time keeping space I see a similar misuse of terms that everyone seems to be swallowing without a second thought. People seem to think that ‘standardizing’ and ‘streamlining’ are one and the same. For example, a common intention is to “streamline our operations by standardizing our pay policies”. One often also swallows this last piece of this sweet but cloudy concoction…”in order to reduce our costs” without a second thought. So here we have the equation:

STANDARDIZING = STREAMLINING = COST REDUCTIONS

Checking a common definition of the word ‘standardize’ we have:

to bring to or make of an established standard size, weight, quality, strength, or the like: to standardize manufactured parts.

By definition, by adhering to standards we reduce variation. But let’s look at the definition of ‘streamline’ we have:

To construct or reconstruct an object to reduce the amount of drag it undergoes as it moves through a fluid, especially air or water.

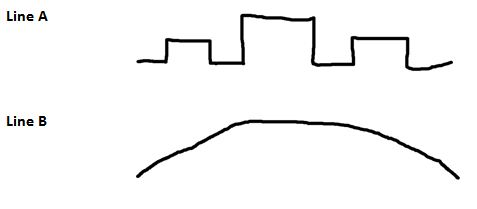

So, my dear barista, how does breaking something up in to standard chunks make it more streamlined? Which line looks like ‘standard parts’ and which line embodies greater variation?

Line A has 3 clearly defined blocks whereas Line B has infinite variation. So which looks more standardized and which looks more streamlined? But wait- didn’t we just say that standardizing IS streamlining? Well, like ordering cream but getting Half-and-Half instead you might be half right. (As for the cost reduction of using twice as much of something that is three quarters the cost I will stir that pot in another blog).

Customers bent on standardizing their pay policies (and thus the Kronos timekeeper configuration) are generally after less variation, not more. Let’s put more people under the same rules and have fewer exceptions to the rules. Sounds good but that is not streamlining. Streamlining, from a scientific perspective (Hey—SCIENCE gave us ULTRA PASTEURIZATION!!!) means balancing two mutually exclusive needs. The needs of the machine to operate, and the effect those parts have on what a layman might call it’s wind resistance. Of course we engineering folk know that’s what we call the ‘wetted area’. (coffee, creamer, wetted area… now are things lining up for you yet?!?)

To put this back into Kronos terms, adding a pay-rule or other configuration element supports the company’s business function but adds viscosity and complexity. But it also may more efficiently accommodate this need than alternative methods. Policies, HR systems, interfaces, payroll costs, maintenance costs it’s all a big complex machine that must be looked at in its entirety. One could, for example, simplify the pay policies only to increase payroll costs due to increases in overtime or shift-differential as an unintended consequence. Similarly, fewer pay-rules are nice but this standardization may increase the complexity of the interfaces downstream.

I urge you to read the label the next time your stakeholders talk about standardizing inherently resulting in streamlining for the organization. Who knows what they’ve been drinking!

Comments